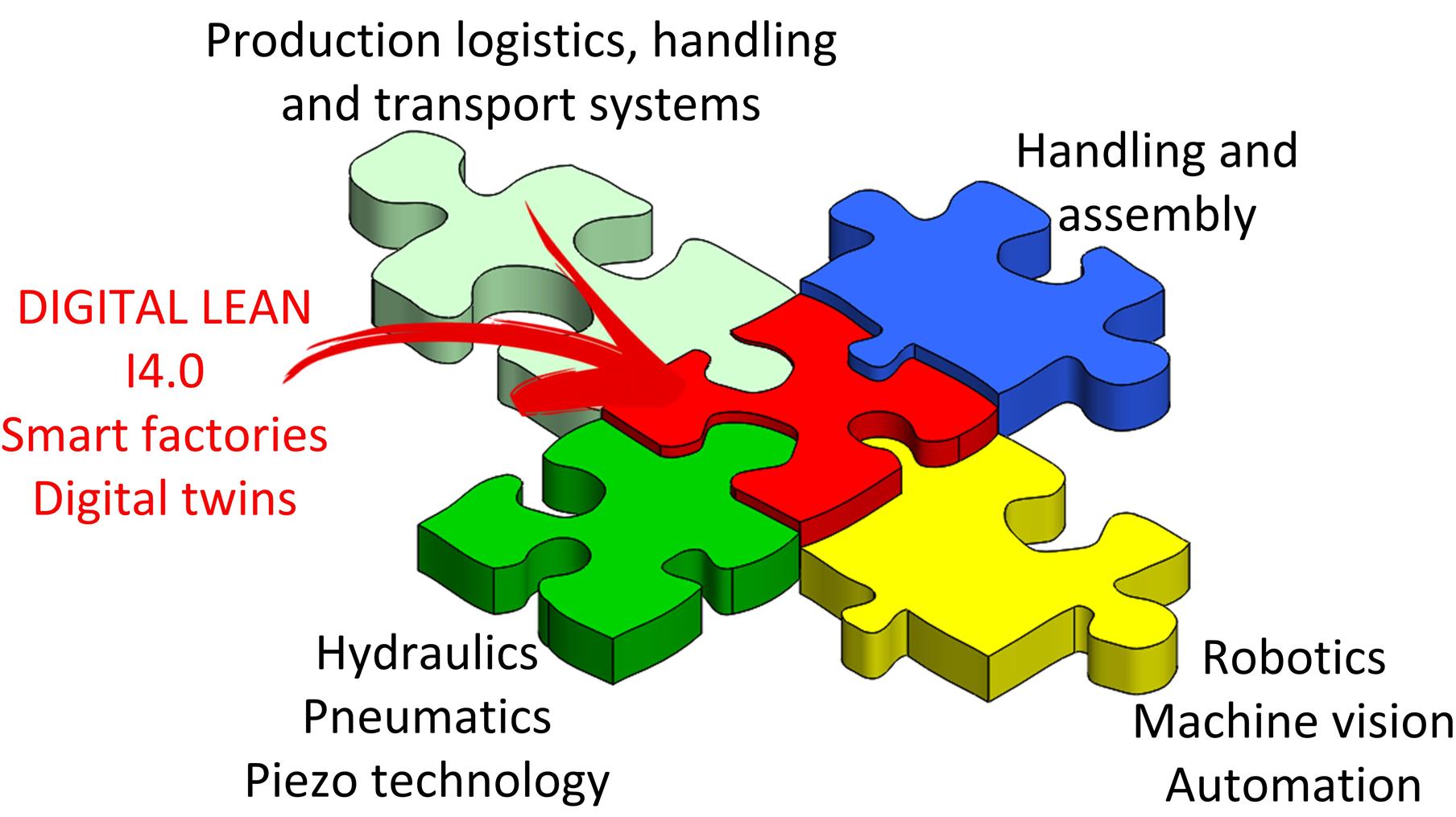

The DIH for digital twins of logistics systems and

manufacturing processes and systems was established within the Laboratory for

Handling, Assembly and Pneumatics (LASIM) of the Faculty of Mechanical

Engineering (UL FME) in Ljubljana. The Faculty is a member of the University of

Ljubljana (UL) and is the largest educational and research institution with the

highest international standards in the field of mechanical engineering in

Slovenia and the wider region of Central and South-Eastern Europe. The

Laboratory for handling, assembly and pneumatics is part of the Department of

Manufacturing, Technologies and Systems of FME, UL. The research and

development priorities of the LASIM laboratory are closely related to the DIH's

focus: digital twins of logistics processes and systems, digital twins of

manufacturing processes and systems, smart factories and Industry 4.0. The

related theme of the laboratory is smart manufacturing, supported by digital

technologies to increase the efficiency of SMEs. The other research areas of

the laboratory are: High Performance Computing (HPC), Cloud Computing, Edge

Computing, Human Centered Production, AI in Manufacturing, Zero Defect

Manufacturing, Distributed Cyber-Physical Systems, Networked Factory, Digital

LEAN, etc.

The main focus of the DIH_DiTMaPS is to support companies in increasing their competitiveness by improving their business and production processes as well as their products and services with the use of digital technologies, especially digital twins. Digital twins are one of the enabling technologies for digital transformation of manufacturing in Industry 4.0 and value chain processes in general. The digital twin is a virtual representation of a physical product or process that serves to understand and predict the performance characteristics of its physical counterpart. Digital twins are used throughout the product lifecycle to simulate, predict and optimize the product and production system before investing in physical prototypes and resources. The DIH will accelerate technology transfer at regional, national and international level, the joint use of research and mobility infrastructures, the support of smart and sustainable entrepreneurship in the field of intelligent factories and the promotion of human capital growth.

Over the years, LASIM has expanded the use of Discrete Event Simulation to include Digital Twins, which are the backbone of Smart factories and I4.0. With the knowledge of cutting-edge technologies and approaches, LASIM has very strong links with industrial partners with R&D projects and activities. Here are some industry partners who are market leaders from different business sectors: Yaskawa Ristro, Yaskawa Europe Robotics, Knauf Insulation, Kolektor, ECOLAB, Danfoss, Krka, Intersocks, Gorenje, Scania, GoodYear, Hidria, Skaza Smart Plastic, Polycom, RIKO, MTZ, LTH Castings, Iskra Mehanizmi, Agromehanika, etc.