-

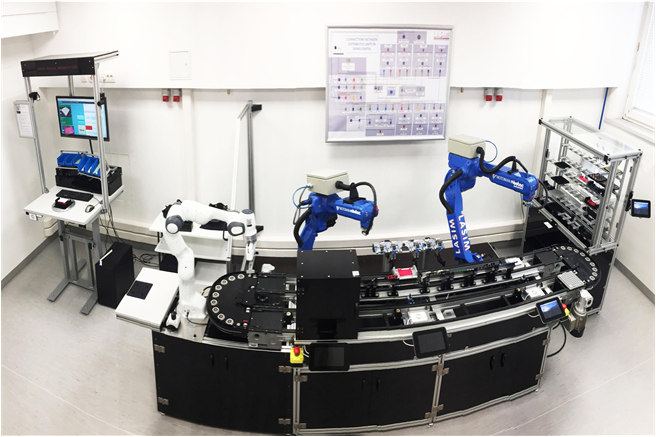

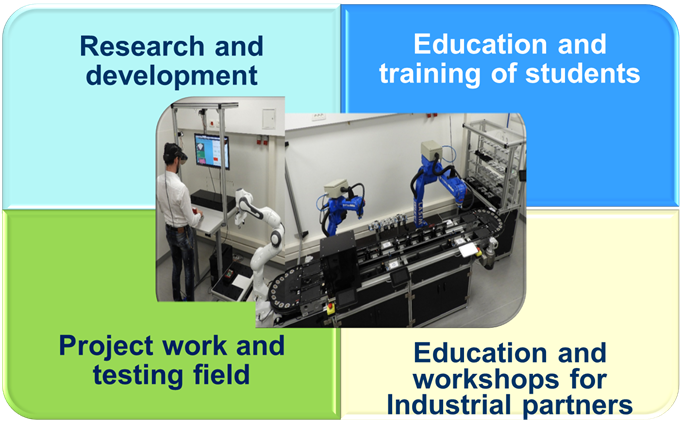

Modern production line with 6 intelligent assembly stations that can be reconfigurable according to the order of assembly processes of products

-

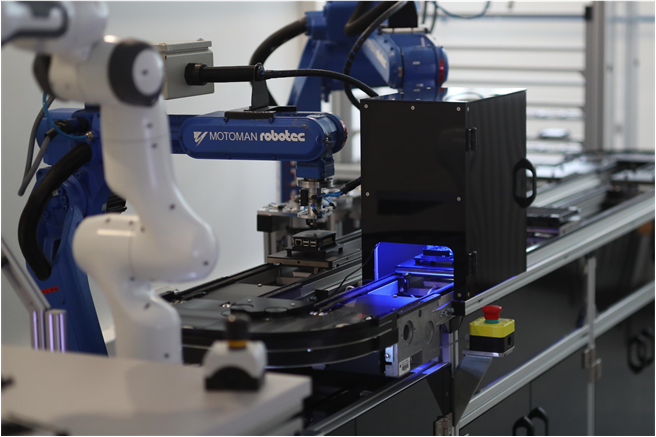

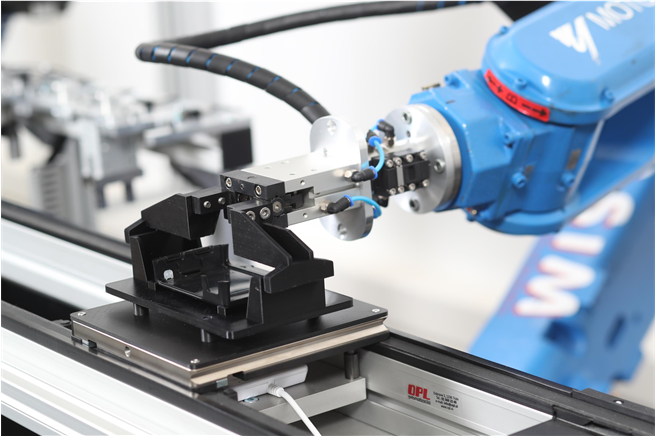

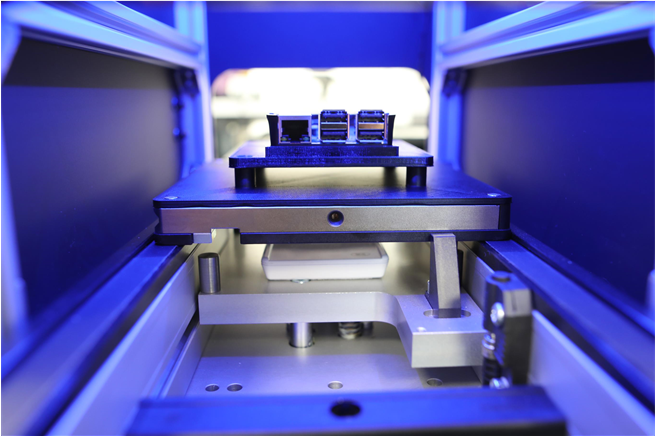

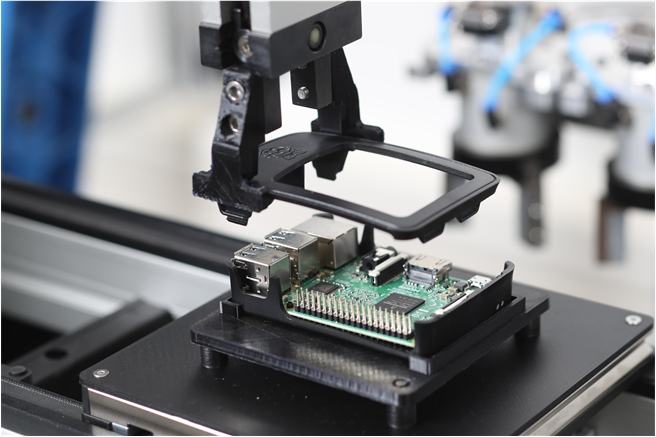

Two robotic cells with the robot gripper tool changers to perform automated robot assembly with the combination of machine vision systems

-

Several handling devices for pick and place operations and other distributed modules such as machine vision systems for different object recognition, RFID systems for tracking the products and operators

-

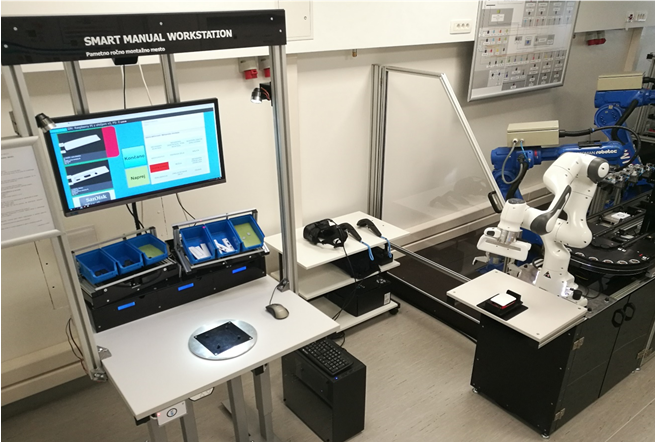

Advanced manual work station with collaborative robot (integration of I4.0 technologies, integration of product management system to perform visualization)

-

3D printers as distributed modules of Smart Factory used to perform products prototyping (to manufacture the new personalized products)

-

Augmented Reality - Meta 2 glasses to perform augmented reality in different areas of production line and individual manufacturing machines

-

Virtual Reality - Oculus Rift glasses used to visualize the objects (systems, production lines, factories) in the development phase

-

LPM - LASIM Production Management Software connects all manufacturing process services (from engineering, supply, warehouse, assembly, logistics and management) and connects them to manual assembly process stations and enables digital LEAN optimised assembly process: assembly material preparation, digital assembly instructions, online and real-time error solving, timing of assembly processes, project status overviews, etc.

-

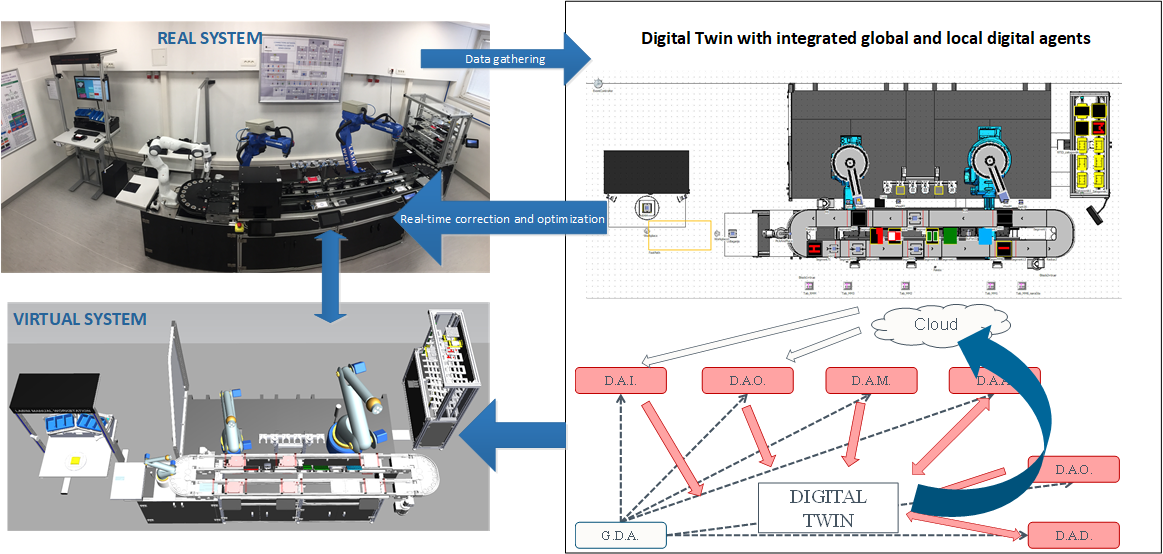

Developed Smart factory platform with integrated Digital Twin, SCADA and distributed PlugAndProduce manufacturing nodes that together form complete hierarchical model.